Hebei Xushi Weiye Machinery Ma

- Thread Rolling Machines

- > Semi-Automatic threading machine

- > CNC automatic threading machine

- > Pneumatic-Automatic threading machine

- > Electric automatic threading machine

- > Hydraulic thread rolling machine

- Butt Welding Machines

- > Manual butt welding machine

- > pneumatic butt welding machine

- Rebar Cutting Equipment

- > Rebar cutting mahcine

- > Rebar sawing machine

- > Steel bar straightening and cutting machine

- Upsetting Machines

- Rebar bending equipemnt

- Machine Parts

- > Thread Rollers

- > Peeling Blades

- > Rebar Coupler

- > Thread Rolling System

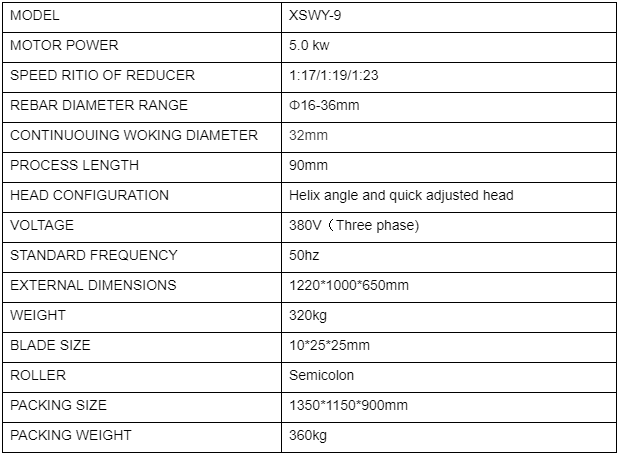

XSWY-9 Rebar threading machine

移动的div

XSWY-9 REBAR RIB-PEELING AND THREAD ROLLING MACHINE

This machine is mainly used in the construction of ribbed steel bar straight screw thread processing, is to achieve reinforced straight thread connection process of key equipment.

It consists of frame, clamp, guide, slide, reducer, stripping rib rolling head, feeding mechanism, automatic opening and closing mechanism, stroke limit structure, cooling system, electrical control box, and control system.

This machine is a unique design, reasonable structure, one-time clamping reinforced rib peeling rolling thread can be completed. Processing speed, a high degree of automation, convenient operation, service life is long, thread rolling round joint additional cost is low. About machining, screw thread does not need other accessories. This equipment is the halogen-light operations, no explosion fire hidden danger, no pollution, high safety, efficiency, can construction 24 hours a day.

Reinforced straight thread ends to make a shape, smooth and standard thread, simple operation, reliable work. To the cooling liquid, the cooling effect is better after using it. A specification of the steel processing, rolling head simply adjust the time, so the procedure is greatly simplified, straight thread machine to overcome the general procedure is repeated cumbersome drawbacks than the average machine efficiency can be increased 2-3 times.

ADVANTAGES

1. The appearance of the box adopts three-dimensional design, which is more novel and firm.

2. The water tank is made of steel plate, and heating rods can be used in winter.

3. The traveling wheels are equipped with bearings ,easy to move.

4. The two sides of the distribution box are closed to enhance safety.

5. The appearance of the motor adopts electrophoresis technology.

6. The reducer reduces the center height and strengthens the stability.

7. Adopting convenient and quick-adjusting helix angle head. Tool holder, positioning plate, carburizing treatment.

8. The transmission shaft is treated with transitional chromium to increase the smoothness of transmission.

9. The voltage display meter is installed, and the voltage level can be observed at any time.

10. Add steel support to improve concentricity and facilitate feeding.

移动的div

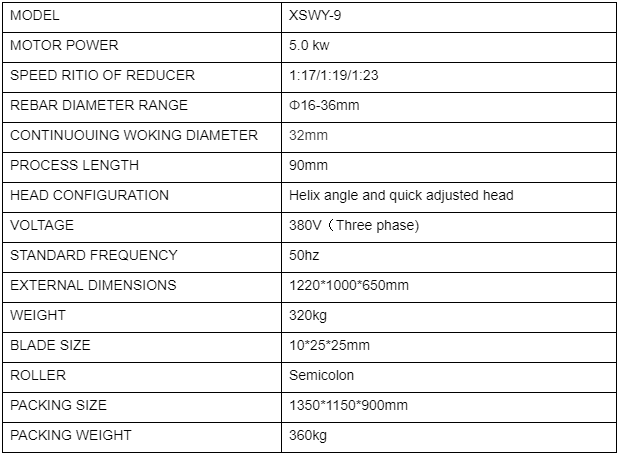

XSWY-9 REBAR RIB-PEELING AND THREAD ROLLING MACHINE

This machine is mainly used in the construction of ribbed steel bar straight screw thread processing, is to achieve reinforced straight thread connection process of key equipment.

It consists of frame, clamp, guide, slide, reducer, stripping rib rolling head, feeding mechanism, automatic opening and closing mechanism, stroke limit structure, cooling system, electrical control box, and control system.

This machine is a unique design, reasonable structure, one-time clamping reinforced rib peeling rolling thread can be completed. Processing speed, a high degree of automation, convenient operation, service life is long, thread rolling round joint additional cost is low. About machining, screw thread does not need other accessories. This equipment is the halogen-light operations, no explosion fire hidden danger, no pollution, high safety, efficiency, can construction 24 hours a day.

Reinforced straight thread ends to make a shape, smooth and standard thread, simple operation, reliable work. To the cooling liquid, the cooling effect is better after using it. A specification of the steel processing, rolling head simply adjust the time, so the procedure is greatly simplified, straight thread machine to overcome the general procedure is repeated cumbersome drawbacks than the average machine efficiency can be increased 2-3 times.

ADVANTAGES

1. The appearance of the box adopts three-dimensional design, which is more novel and firm.

2. The water tank is made of steel plate, and heating rods can be used in winter.

3. The traveling wheels are equipped with bearings ,easy to move.

4. The two sides of the distribution box are closed to enhance safety.

5. The appearance of the motor adopts electrophoresis technology.

6. The reducer reduces the center height and strengthens the stability.

7. Adopting convenient and quick-adjusting helix angle head. Tool holder, positioning plate, carburizing treatment.

8. The transmission shaft is treated with transitional chromium to increase the smoothness of transmission.

9. The voltage display meter is installed, and the voltage level can be observed at any time.

10. Add steel support to improve concentricity and facilitate feeding.

Loading ...