Welcome to Hebei Xushi Weiye Machinery Manufacturing Co., Ltd. website!

Revolutionizing Construction: The Benefits of CNC Automatic Re-Bar Rib Peeling and Thread Rolling

Release Time:

May 03,2025

In the realm of industrial equipment and components, particularly within the lifting machinery sector, the processing of reinforcement bars (rebar) is crucial for ensuring the structural integrity of various constructions. CNC automatic re-bar rib peeling and thread rolling technologies play a pivotal role in this process. Understanding these technologies can significantly benefit professionals in

CNC (Computer Numerical Control) automatic re-bar rib peeling is a process that meticulously removes the ribs of rebar to create a smooth surface. This smoothness is essential as it facilitates better bonding with concrete, thereby enhancing the structural strength of the finished product. The precision of CNC technology allows for uniform peeling, resulting in consistent quality across batches. This helps in minimizing material wastage and ensures that the rebar can be easily manipulated or bent as required during construction.

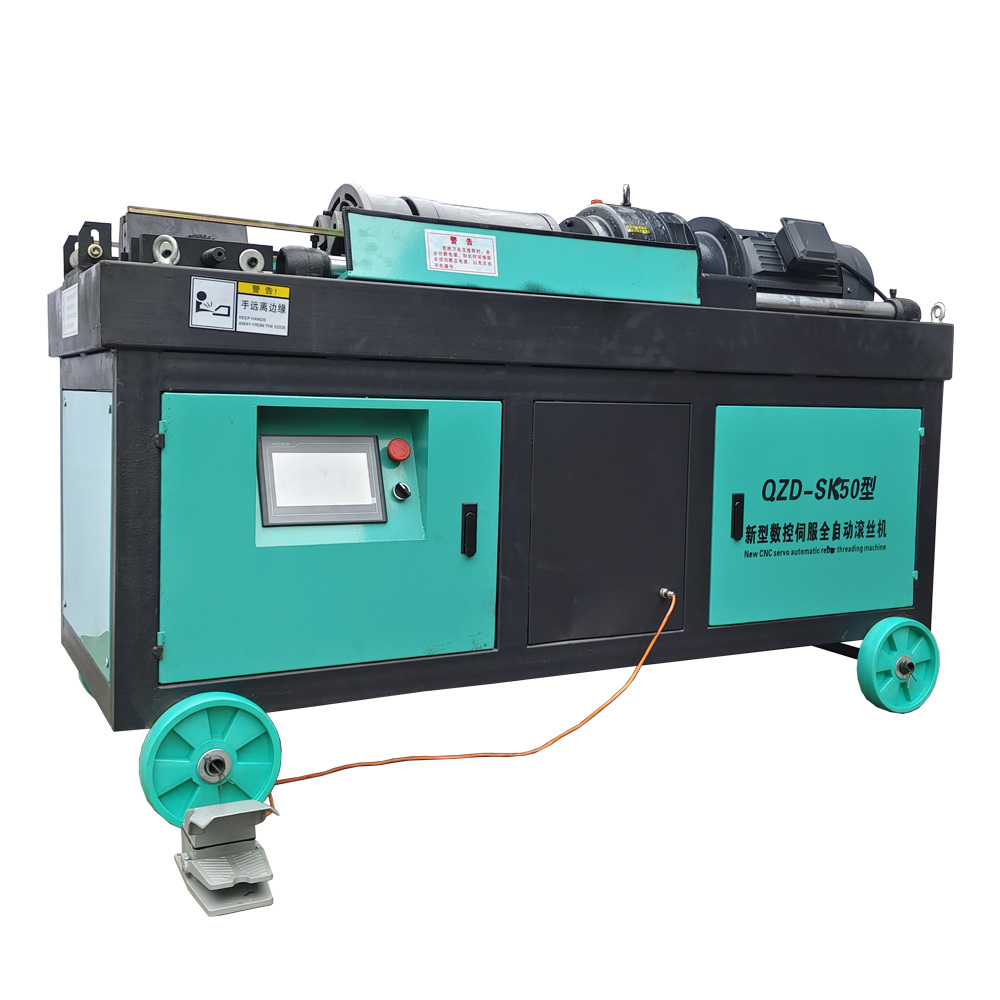

Following the peeling process, the next step is thread rolling. This technique involves the creation of threads on the rebar for subsequent connections. Unlike traditional methods, CNC thread rolling is performed with remarkable accuracy and speed, which not only increases production rates but also reduces the likelihood of defects. The threads produced are robust and reliable, ensuring that connections between rebar sections remain secure, which is vital for the overall safety of construction projects.

In addition to enhancing the quality of rebar, CNC automatic processes also deliver significant time and labor savings. Automation reduces the need for manual labor in peeling and rolling, allowing workers to focus on other critical tasks while simultaneously increasing throughput. This efficiency can lead to reduced project timelines, enabling construction companies to meet deadlines and manage resources more effectively.

Moreover, the integration of CNC technology in rebar processing aligns with the industry’s growing emphasis on sustainability. By minimizing waste and optimizing material use, manufacturers contribute to more environmentally friendly practices. The enhanced precision also means fewer errors, further reducing the need for rework and additional resources.

Overall, CNC automatic re-bar rib peeling and thread rolling not only streamline the production of reinforcement bars but also improve the quality and safety of construction projects. For professionals in the lifting machinery sector, adopting these advanced technologies presents an opportunity to stay competitive in a rapidly evolving industry. Understanding and implementing these processes can lead to better project outcomes, ensuring that structures built today stand the test of time.

Keywords:

More information

Hebei Xushi Weiye

CONTACT US

Add: Qiaoxi street,Wuqiang county, Hengshui, China

Email: info@xswy-machinery.com

Wechat: Amanda_XUSHIWEIYE

Whatsapp: +8615933856555

Follow Us

Copyright © Hebei Xushi Weiye Machinery Manufacturing Co., Ltd.

Powered by: 300.cn Shijiazhuang SEO | Privacy Policy