Welcome to Hebei Xushi Weiye Machinery Manufacturing Co., Ltd. website!

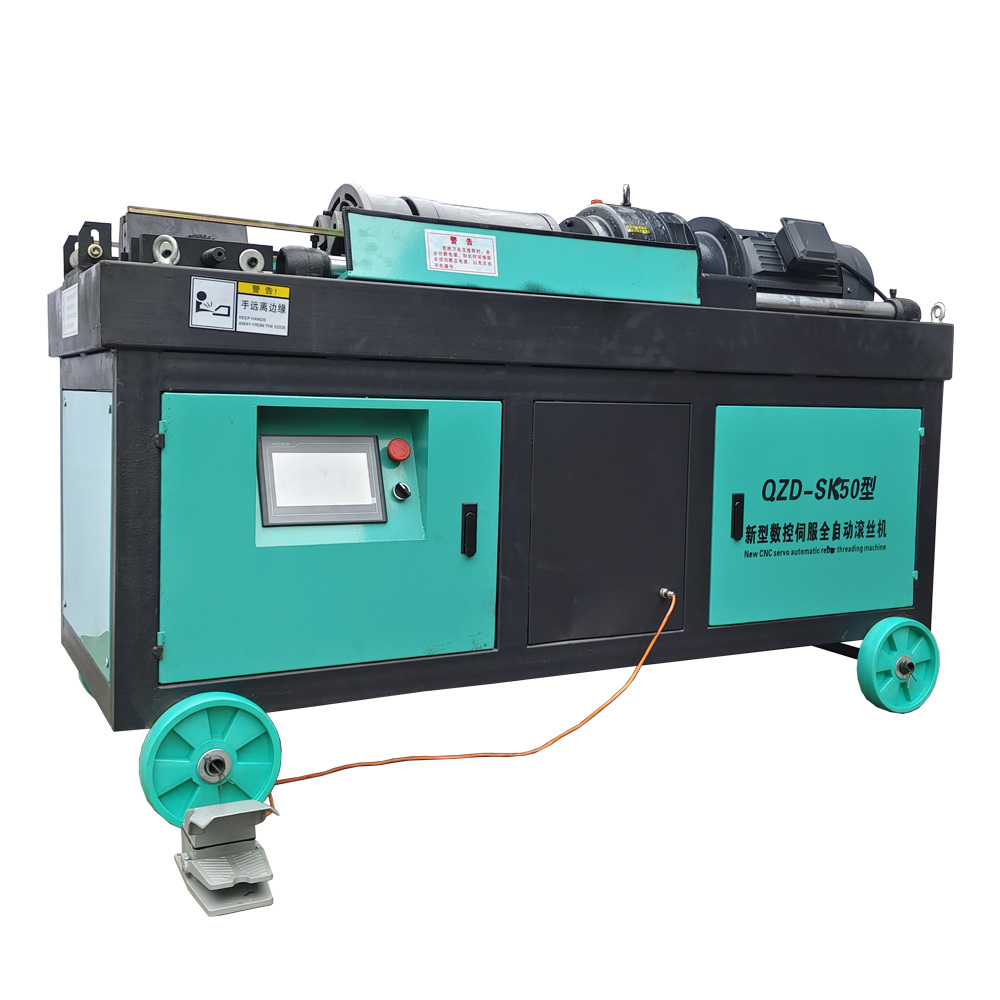

Revolutionizing Construction: The Role of CNC Automatic Re-bar Rib Peeling and Thread Rolling in Modern Lifting Equipment

Release Time:

May 06,2025

In the modern industrial landscape, the demand for efficiency and precision is ever-increasing, particularly in sectors like construction and heavy manufacturing. One of the technological advancements leading this charge is the CNC (Computer Numerical Control) automatic re-bar rib peeling and thread rolling processes. These innovations are proving to be game-changers for lifting equipment manufact

CNC automatic re-bar rib peeling focuses on enhancing the performance of re-bars, which are crucial for reinforced concrete structures. The rib peeling process removes imperfections and ensures a smooth surface, which is vital for increasing bond strength between the re-bar and concrete. By employing CNC technology, manufacturers can achieve consistent quality and minimized waste during production. This consistency not only improves the structural integrity of buildings but also significantly reduces the likelihood of defects that could lead to costly repairs or safety hazards.

Thread rolling, another critical component of this technology, creates high-strength threads on re-bars that facilitate secure connections. The advantages of thread rolling over traditional cutting methods include a significant reduction in material loss and the enhancement of mechanical properties. The rolled threads maintain the material's grain structure, which results in stronger and more durable connections in construction applications. This is particularly beneficial in lifting equipment, where safety and reliability are paramount.

Moreover, the automation aspect of CNC technology cannot be overstated. By utilizing automated systems, manufacturers can increase production rates and reduce labor costs. Automation minimizes human error, which is crucial in high-stakes environments, thus ensuring that products meet rigorous safety standards. This level of precision and reliability is essential for lifting machinery, where any failure can lead to catastrophic consequences.

Additionally, the integration of CNC technology in re-bar processing contributes to sustainability efforts. By optimizing material usage and reducing waste, companies can lower their environmental impact while also enhancing their operational efficiency. This not only meets regulatory requirements but also aligns with the increasing market demand for sustainable construction practices.

In summary, CNC automatic re-bar rib peeling and thread rolling represent critical advancements in industrial equipment, especially in the lifting machinery sector. These processes enhance the quality, efficiency, and sustainability of construction materials, providing significant benefits to manufacturers and end-users alike. As demand for innovative and reliable construction solutions continues to grow, embracing these technologies will be essential for staying competitive in the market.

Keywords:

More information

Hebei Xushi Weiye

CONTACT US

Add: Qiaoxi street,Wuqiang county, Hengshui, China

Email: info@xswy-machinery.com

Wechat: Amanda_XUSHIWEIYE

Whatsapp: +8615933856555

Follow Us

Copyright © Hebei Xushi Weiye Machinery Manufacturing Co., Ltd.

Powered by: 300.cn Shijiazhuang SEO | Privacy Policy