Welcome to Hebei Xushi Weiye Machinery Manufacturing Co., Ltd. website!

Maximizing Efficiency with CNC Automatic Re-bar Rib Peeling and Thread Rolling in Industrial Equipment

Release Time:

Jun 07,2025

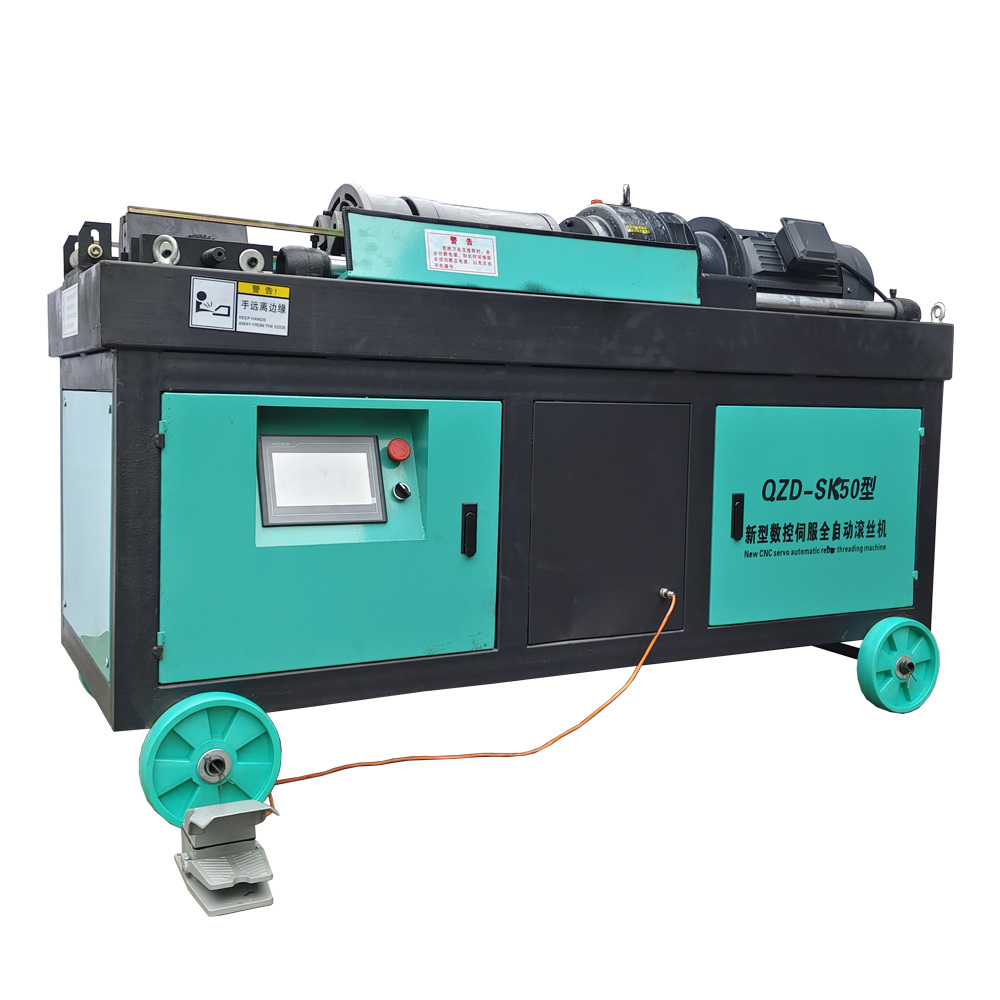

In the realm of industrial equipment, particularly in the lifting machinery sector, efficiency and precision are paramount. One of the innovations that have significantly influenced this field is the CNC automatic re-bar rib peeling and thread rolling technology. This process not only enhances product quality but also optimizes production efficiency, making it an essential consideration for busine

CNC (Computer Numerical Control) technology allows for the automation of machinery, leading to highly precise operations. In the case of re-bar rib peeling, it involves the removal of ribs from the surface of re-bars, which is crucial for subsequent processes such as threading. The significance of this step cannot be understated; ensuring a smooth surface on re-bars is vital for achieving strong and reliable connections in construction applications.

Thread rolling, on the other hand, is a process that forms threads onto the re-bar, improving its ability to connect with other elements in construction frameworks. The combination of rib peeling and thread rolling using CNC technology results in a more uniform and reliable product, which is essential for the structural integrity of any construction project. This technology minimizes human error, enhances repeatability, and ultimately leads to higher quality standards.

Investing in CNC automatic re-bar rib peeling and thread rolling not only contributes to better product quality but also significantly reduces production time. By automating these processes, companies can streamline their operations, which allows for faster turnaround times and increased output. This is particularly beneficial in industries where time is critical, such as construction, where delays can lead to significant financial losses.

Moreover, the integration of CNC technology in these processes aligns with modern manufacturing trends focused on sustainability and resource efficiency. By reducing waste and optimizing material usage, businesses can also adhere to environmental regulations and promote sustainable practices, which are increasingly becoming a requirement in today’s market.

In conclusion, for companies in the industrial equipment sector, particularly those dealing with lifting machinery, CNC automatic re-bar rib peeling and thread rolling technology represents a significant advancement. The benefits of this technology reach beyond just improving product quality; they also encompass enhanced operational efficiencies, reduced waste, and the ability to meet the ever-increasing demands of the construction industry. Adopting these innovations could serve as a key competitive advantage for businesses looking to thrive in a rapidly evolving marketplace.

Keywords:

More information

Hebei Xushi Weiye

CONTACT US

Add: Qiaoxi street,Wuqiang county, Hengshui, China

Email: info@xswy-machinery.com

Wechat: Amanda_XUSHIWEIYE

Whatsapp: +8615933856555

Follow Us

Copyright © Hebei Xushi Weiye Machinery Manufacturing Co., Ltd.

Powered by: 300.cn Shijiazhuang SEO | Privacy Policy